Summer Update: From Backyard Sugarer to Commercial Syrup Production

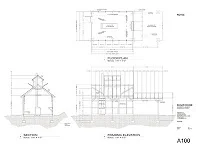

Drawing of the proposed Waterfall Mtn. Sugar House. Aaron Floyd (copyright, May 2010)

July 20, 2010. And the Sugar House will rise!

Things do move slower in the mountains,

or so it seems sometimes. I certainly have a harder time continuing my break-neck multi-tasking ways when I am there. The beauty and the harshness slow you down. The steep hills, the rough winters, ....and the meadows and forests so rich with life and beauty that one is spellbound immediately upon entering this world. Ahh...it is summer in the highlands of the Blue Ridge...morning dew, the gentle breeze laced with complex sweetness, deep earthiness... and the people, up at sunrise, are busy as bees maximizing the coming bounty of fall as the inevitable struggle of winter will quickly follow.

Up at Doug Munroe's farm, on the NE side of the amphibolite mountains, preparation is full steam ahead...but not for the resulting fruits of summer and fall. Late winter brings its own sort of sweetness. The sugar maple tree

(Acer saccharum)

gifts its sucrose, nearly all at once, to those that are prepared to receive it!

Here is an update on Doug's effort to shift from simple backyard syrup production to commercial viability:

The utility lines are in

, and RAFI (Rural Advancement Foundation International) has given this stage of construction a thumbs up. Approval on standards and quality was verified today! With major equipment arriving in October, sugar house construction must begin at once.

Over the last 4 months

much preparation and planning has taken place. The site was prepared, wood milled, and plans were drawn up. Doug received a sugar house design from the University of Vermont, but the plans did not quite suit the planned site. Doug worked with

Aaron Floyd to come up with a new design that would meet the unusual needs of a mountain-side site.

For detailed plan drawings, see PDF file:

(by Aaron Floyd, 05/27/2010)

A volunteer sugar house construction effort

will take place from August 2-7. This will mostly be a family affair, with sisters, brothers, mothers, fathers, children, cousins and friends coming from afar to lend a hand. There should be four generations on hand. The goal will be to get the structure up and the roof on....in 5 days.

This week the

horses will return

to assist in the moving of milled sills and posts. With the help of those strong horses and some skilled and hardworking individuals, the sill plates, the posts, and a concrete pad should all be installed in plenty of time for the volunteer construction arriving in early August. Doug has already assigned volunteer roles, job boss included.

Black Locust is the wood of choice

for these parts of the house. It is an Appalachian farm-use staple

(see Native Range Map).

The rot resistant wood is used frequently for fence posts, and it burns hot, lending itself well for heat production in the winter months. Locust posts have been known to last a lifetime in the ground, so this locally growing species of tree is the perfect choice for sill plate material! I should mention that this tree is considered a nuisance by many, as it is hardy and aggressive. This early successional pioneer plant will send up many new shoots when cut to the ground...you will find it advancing into freshly abandoned fields and roadsides (you may even find a fence post sprouting!). Like many hardy and invasive plants, this one can be utilized for so many things. Last spring, my nose utilized the trees' super sweet droop of creamy white flowers!

Species

Fact Sheet:

If you would like to join this volunteer effort, contact Doug Munroe at 336-385-6507.

Image Sources:

>Illustrations copyright Aaron Floyd, 2010.

>Black Locust illustration borrowed from the Forest Service Silvics manual: http://www.na.fs.fed.us/pubs/silvics_manual/volume_2/robinia/pseudoacacia.htm

Links to prior articles:

Introduction 2009

November update, 2009

December update, 2009

February update, 201o

March update, 2010